Motion Control Systems

HOME > Products > Motion Control Systems > Rotary Cutter

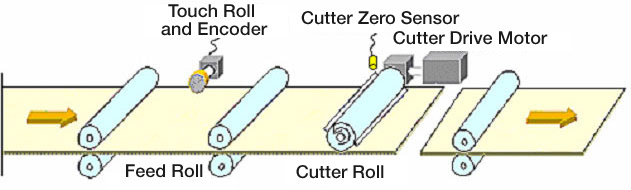

Rolled heavy paper, cardboard, etc. is cut perpendicular to the moving line into the predetermined size. Size Cutting

Rotary Cutter

Materials are cut at constant length set by the interface panel.

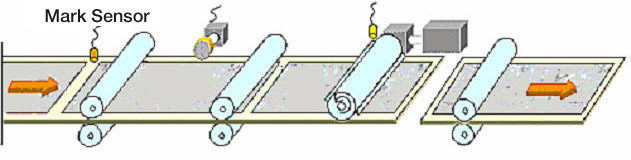

Mark Cutting

Materials are cut at constant length measured by the mark sensor.

Current length value is calculated based on conveyor line speed driven by the feed rolls. Without the speed control of the feed rolls, the pulse from the encoder attached on the inverter driven conveyor is calculated. With the speed control of the feed rolls, the pulse from the encoder in the servo motor that drives the feed rolls is calculated.

Unlike the printer, the speed of the rotor is adjustable. To achieve smooth actions on the machine, the smooth function can be used. This also functions as the modified trapezoid for the variable-speed pattern.

Servo Integral Uniaxial Machine Controller (Sizing Cut)

With the speed control, the servo pack for the feed roller drive is placed separately.

• Traditional rotary cutters start and stop at every cut. Motor capacity increases. However, the rotary cutter in the above machine controller system keeps rotating without starting or stopping due to the special cam pattern (cutter may rotate in the reverse direction as well).

• Motor load current can be reduced by approximately 20% for an increase in energy savings. The motor frame can be one size smaller when certain conditions are met.

• High-accuracy cutting (±0.1mm) with the ultrafast computation (scanning time: 2.0ms)